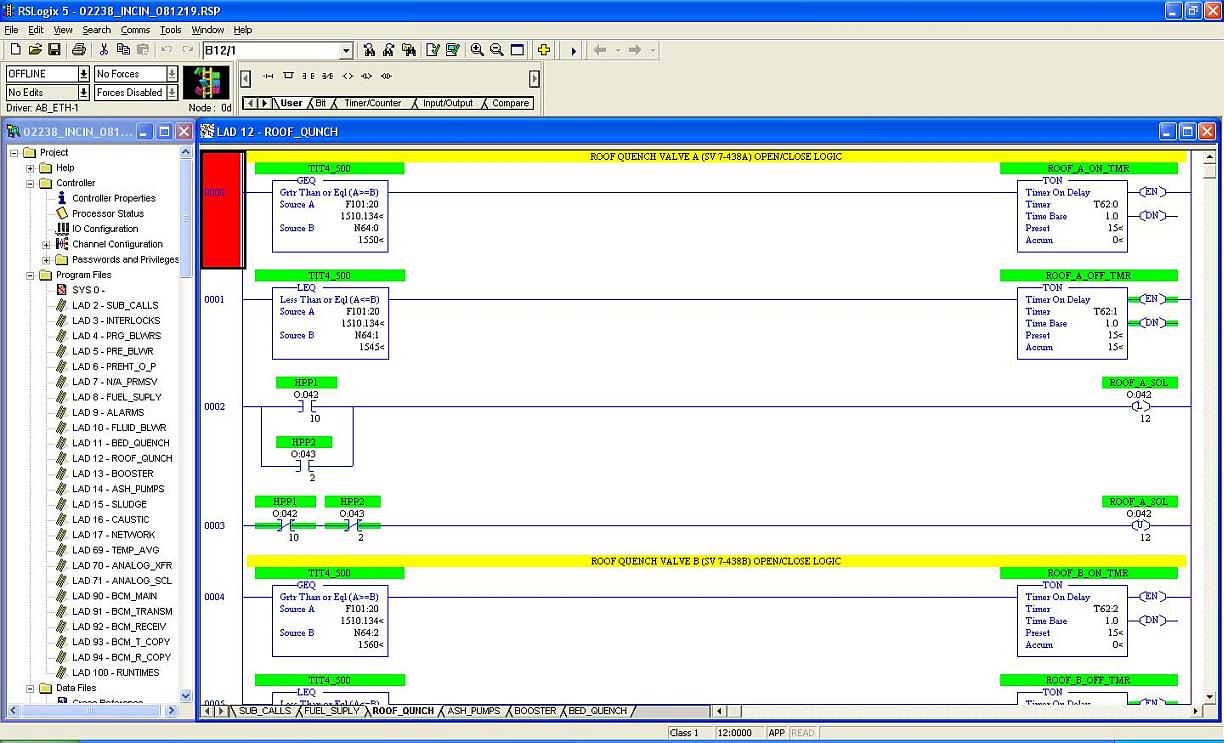

The drawbacks of these systems are that they’re often costly and are locked to a specific OEM. The simulation results they provide are highly accurate to an actual PLC.

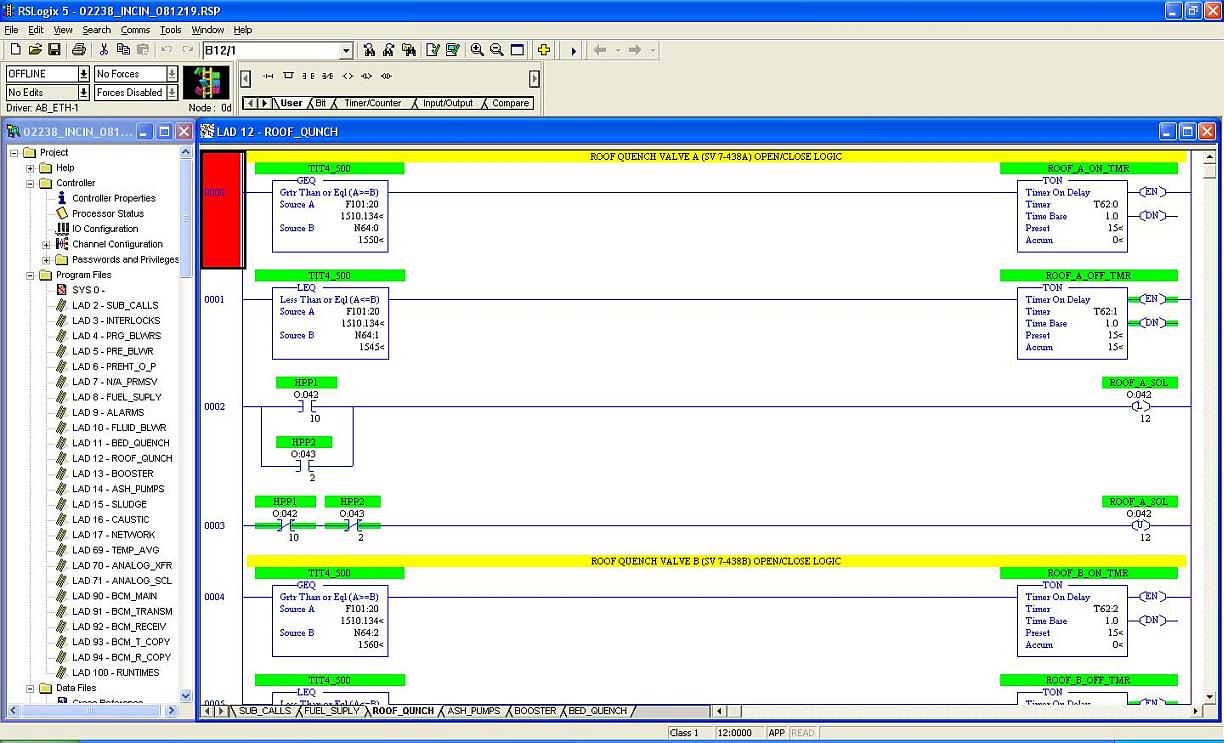

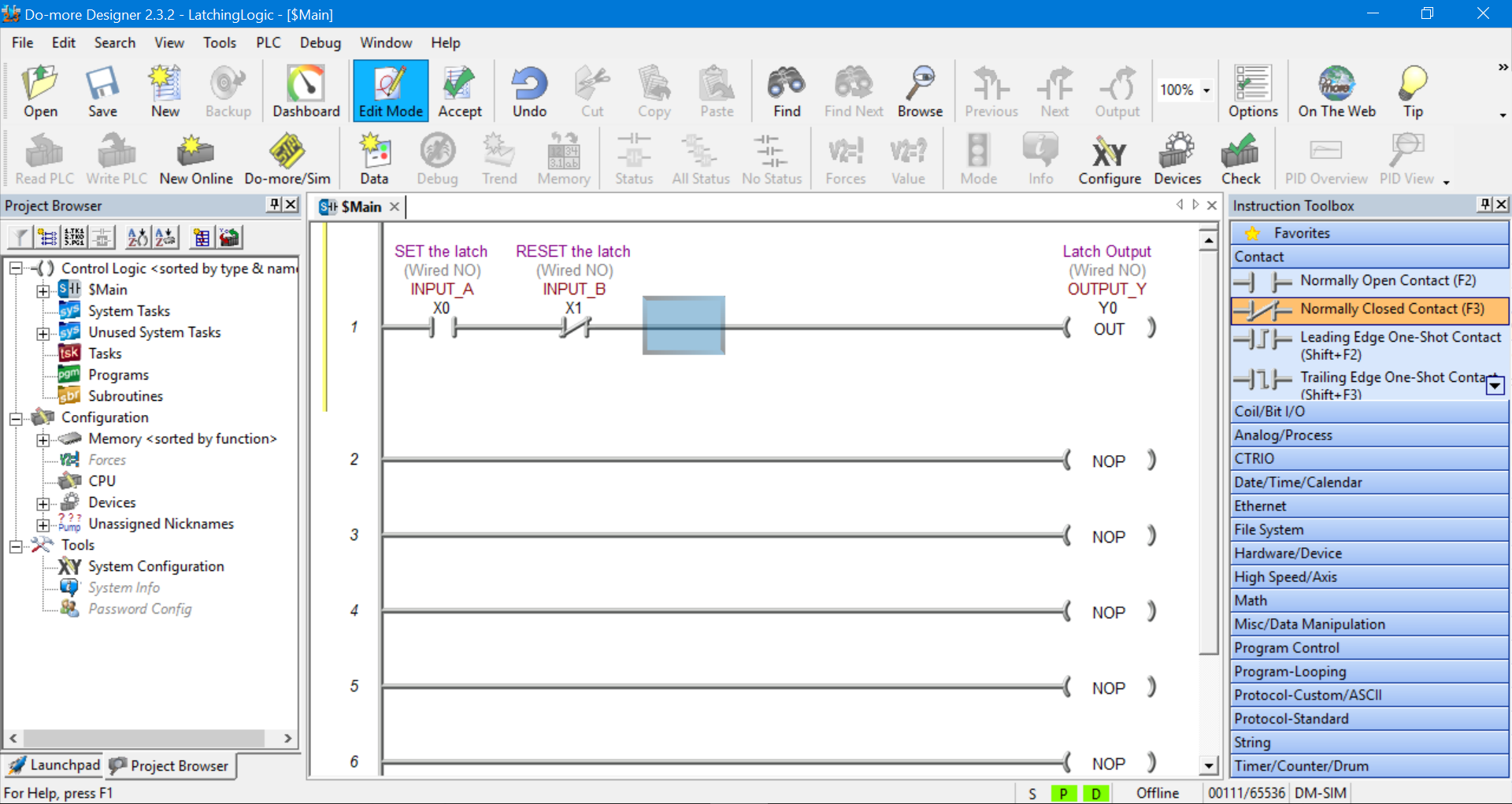

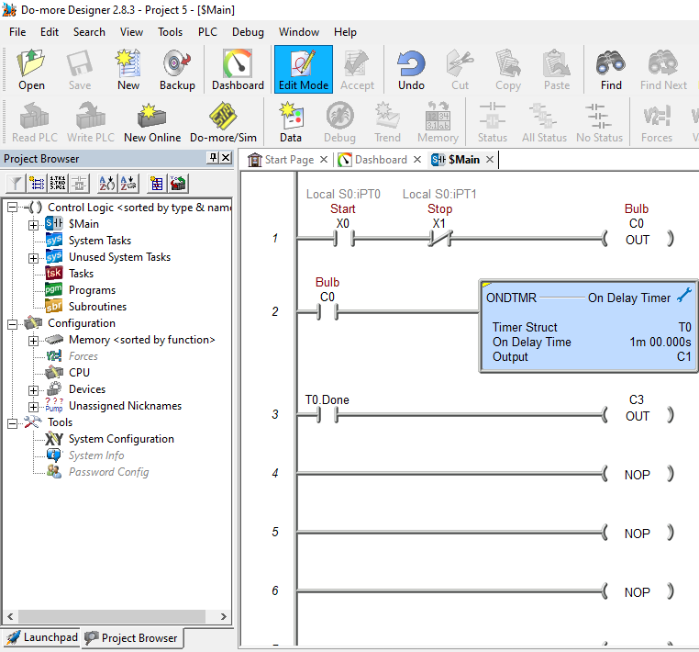

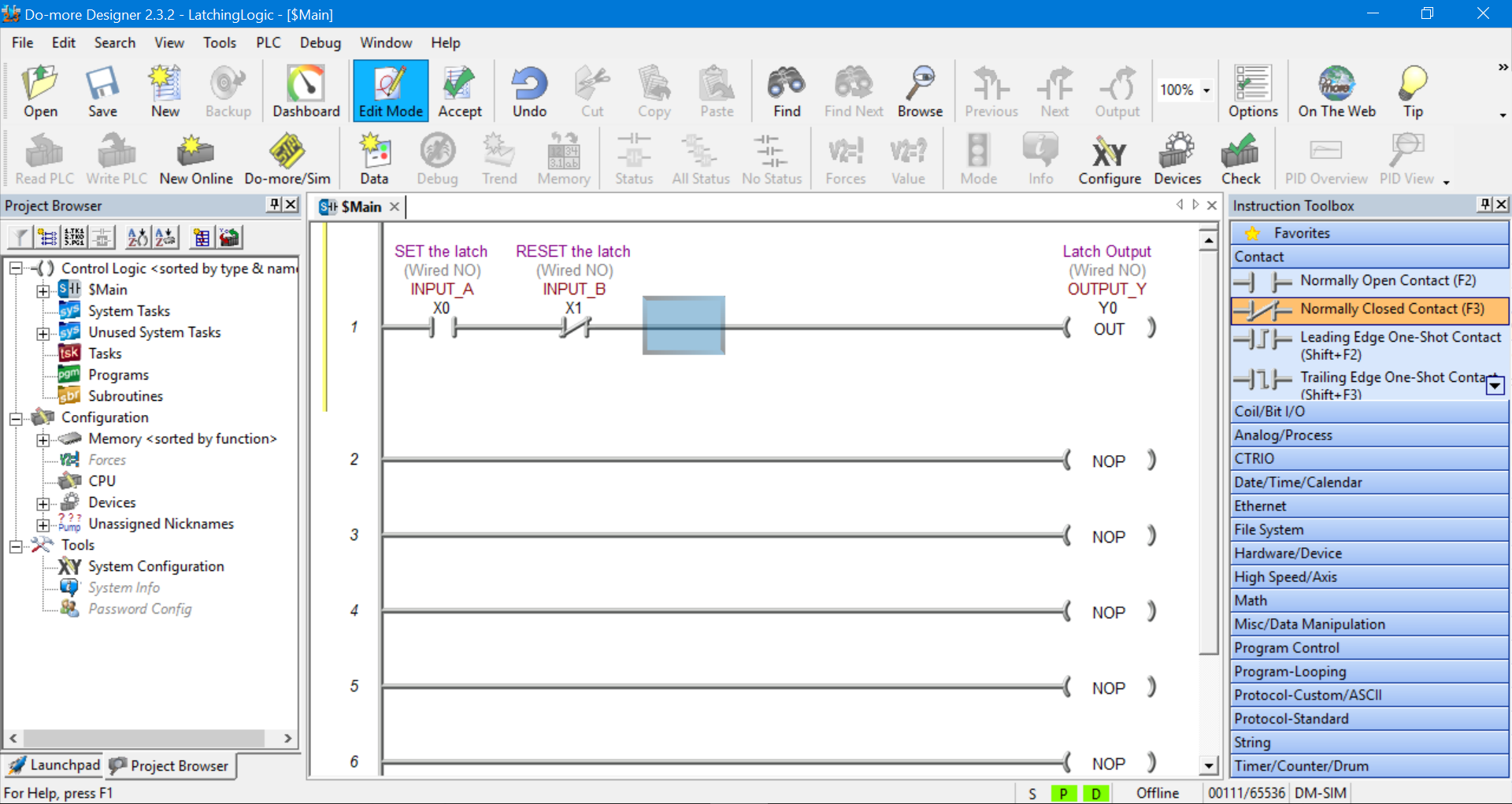

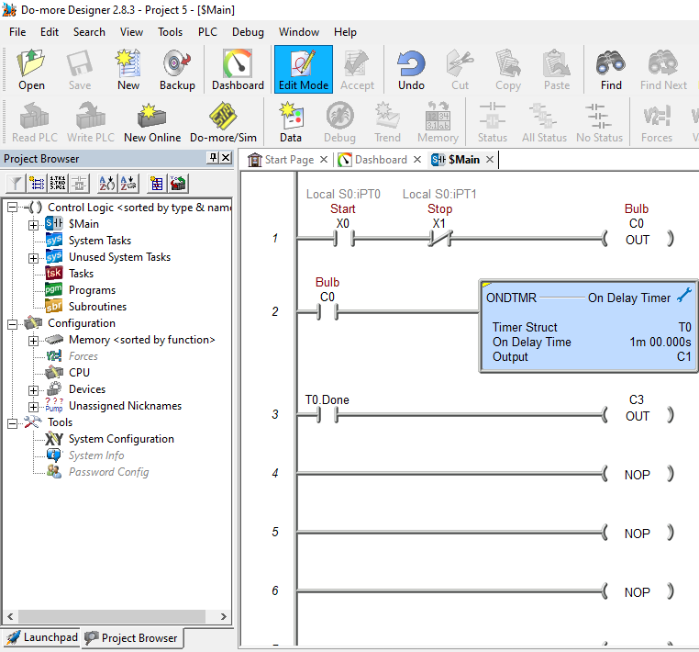

The code is run directly from the file that will be used on an actual PLC. The advantage of native PLC simulators are as follows: An example for Allen Bradley would be an RSLogix Emulate environment that would simulate the code that would run on an RSLogix 500 based PLC. Most Original Equipment Manufacturers (OEMs) provide (generally at a price) a means to simulate their PLC programs. There is a vast difference between various PLC simulators on the current market. Furthermore, it is possible to access online tools that will simulate basic PLC programs on a web server and allow users to practice building PLC software without the need of any additional software installation. It is possible to use programs that will run code written for a PLC on a regular laptop or desktop computer. How do you simulate a PLC?Ī PLC is a robust industrial processor that reads inputs, executes a set of internal instructions and sets outputs accordingly. Lastly, as a PLC simulator is software based, users aren’t required to purchase additional components that are often very costly. A PLC simulator is often used for training and learning purposes as it allows users to test various logic configurations without any impact on external hardware. Such software allows the engineer to save time on commissioning, minimize system critical errors and uncover potential system deadlocks. It allows us to make changes before the circuit is implemented, reducing the risk of errors and accidents.Ī PLC simulator is a piece of software that allows the programmer to test their code without the actual hardware. And seventh, it helps to identify potential risks and hazards associated with the circuit program. Thus, it provides greater flexibility in experimentation. Sixth, it allows for testing different scenarios without physical changes to the control circuit. Why? Because physical testing can be affected by external factors. Fifth, it provides a more accurate representation of the circuit's behavior than physical testing. Fourth, you gain an understanding of how the program works, how it interacts with various inputs, and how it produces outputs. Third, it allows for the testing of the circuit program without the need for actual hardware, which can save time and resources.

The code is run directly from the file that will be used on an actual PLC. The advantage of native PLC simulators are as follows: An example for Allen Bradley would be an RSLogix Emulate environment that would simulate the code that would run on an RSLogix 500 based PLC. Most Original Equipment Manufacturers (OEMs) provide (generally at a price) a means to simulate their PLC programs. There is a vast difference between various PLC simulators on the current market. Furthermore, it is possible to access online tools that will simulate basic PLC programs on a web server and allow users to practice building PLC software without the need of any additional software installation. It is possible to use programs that will run code written for a PLC on a regular laptop or desktop computer. How do you simulate a PLC?Ī PLC is a robust industrial processor that reads inputs, executes a set of internal instructions and sets outputs accordingly. Lastly, as a PLC simulator is software based, users aren’t required to purchase additional components that are often very costly. A PLC simulator is often used for training and learning purposes as it allows users to test various logic configurations without any impact on external hardware. Such software allows the engineer to save time on commissioning, minimize system critical errors and uncover potential system deadlocks. It allows us to make changes before the circuit is implemented, reducing the risk of errors and accidents.Ī PLC simulator is a piece of software that allows the programmer to test their code without the actual hardware. And seventh, it helps to identify potential risks and hazards associated with the circuit program. Thus, it provides greater flexibility in experimentation. Sixth, it allows for testing different scenarios without physical changes to the control circuit. Why? Because physical testing can be affected by external factors. Fifth, it provides a more accurate representation of the circuit's behavior than physical testing. Fourth, you gain an understanding of how the program works, how it interacts with various inputs, and how it produces outputs. Third, it allows for the testing of the circuit program without the need for actual hardware, which can save time and resources.

Second, you can identify design flaws and adjust parameters to improve the circuit's performance and safety. First, it allows for error detection in the control circuit program before it is implemented in real-life situations. Mastering the simulation process in Siemens Logo PLC can provide several benefits.

0 kommentar(er)

0 kommentar(er)